Cleaning Your Units

Cleaning the Counters

Counters will often get quite dirty when placed in the field. If the counter is dirty or muddy, you can safely wash it with water, but first make sure that the nozzle caps are installed to prevent water from going into the air switch. If you need to remove permanent marker, rubbing alcohol works good. If you need to remove tape residues, then "goof-off" and similar products are good. None of these solvents will harm the PicoCount counters. You should only use water or rubbing alcohol when cleaning the NanoCount 1000 units. If water or alcohol somehow gets into the air switch nozzles, you need to dry them out before trying to use the units. To do this position the counter with the nozzle facing straight down and keep it this way until the unit has completely dried. Strong solvents like "goof-off" can damage the air switch assemblies, so try to avoid getting it in the nozzles.

Clearing Debris From Nozzles

Occasionally an air switch will become weak or non-functional due to debris getting into the air switch nozzle.. The most common source of this debris is particles and fibers from deteriorating rubber hose. Another source of debris is dirt and salts that get into an uncovered nozzle when the counter is placed in the field. If a channel is not going to be used, try to make sure that the unused channel is sealed off. We supply rubber caps when we ship the units. These caps should keep out unwanted debris and water.

Over the years we have encountered many counters with rubber particles and dirt that were causing the air switch response to be weak until they were cleared out. We have also encountered other things in the nozzles... one time we found a spider nest in the nozzle. Another time we found a tar like substance in a nozzle, but we could not clean it out so that the air switch would work, this unit was declared non-repairable and returned. Once we received a counter with pink paint splashed on it, and some of it went into one of the nozzles. Needless to say, that one was not repairable either. So be careful with unused nozzles and make sure they stay capped, especially when in the field. If you suspect there might be debris in a nozzle, follow the below instructions to clear it out.

Clearing Debris From PicoCount 2500 Nozzles

To clear debris from the counter nozzles, you will need a straight piece of wire 4 to 6 inches in length (like a paper clip straightened out), or better a straight dental pick with a crook at the end. For PicoCount 2500 units with serial numbers earlier than 1309XXXX, you need to probe the nozzle channel carefully, the air switch can be damaged with aggressive cleaning. Starting with serial number 1309XXX the air switch is considerably more rugged and cannot be damaged very easily.

If you have a straight piece of wire 5 or 6 inches in length and you just let it drop under gravity, you should hear it hit the sensor plate. If you have the counter hooked up to TrafficViewer Pro and have it in "live data view" you will see counts register, unless debris is interfering.

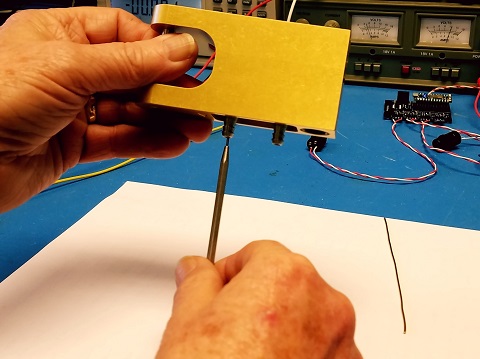

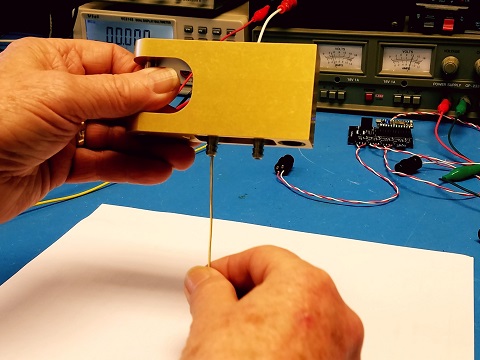

To clear the debris, turn the counter so the nozzles are facing downward. It is best to do this over a blank sheet of white paper, so that you can see if debris is being dislodged. Then insert the wire or dental pick into the nozzle, it should go in about an inch. Then stroke the wire or pick up and down. If you are using a dental pick, you can also spin it around, wiggling it back and forth. If debris begins falling out, you can occasionally remove the wire or pick and tap the counter against the table top to dislodge debris that is in the cavity in front of the air switch. The crook at the end of the dental pick helps get to debris in the cavity.

Clearing Debris From PicoCount 4500 and NanoCount 1000 Nozzles

In the PicoCount 4500 and NanoCount 1000, the air switch assembly is mounted at a right angle to the nozzle channel. This being the case, you can aggressively clean the nozzle channel without having to worry about damaging the air switch. Since the air switch cannot be "touched" by the probes you will not see counts in "live data view" while cleaning or probing these units.

To clear the debris, turn the counter so the nozzles are facing downward. It is best to do this over a blank sheet of white paper, so that you can see if debris is being dislodged. Then insert the wire or dental pick into the nozzle, it should go in about an inch. Then stroke the wire or pick up and down. If you are using a dental pick, you can also spin it around, wiggling it back and forth. If debris begins falling out, you can occasionally remove the wire or pick and tap the counter against the table top to dislodge debris that is in the cavity in front of the air switch. The crook at the end of the dental pick helps get to debris in the cavity.