Setting Your Counter Up To Collect Data

Securing Your Counter

- Secure your counter with a chain and padlock.

- The chain needs to be around something that somebody cannot lift it over. A tree or a light pole for example.

- The counter should be secured to something from the very moment it is put out until the moment it is picked up. Securing the counter is not just to prevent theft, but also to prevent the counter from getting dragged down the street if a vehicle somehow catches and drags a hose.

Securing The Hose

If you are working on pavement with paved shoulders you will want to drive a nail into each shoulder, leaving the nail head sticking up slightly from the pavement (where in just a minute you will attach a rope loop).

If you have no paved area on the sides of the road to attached to and it is packed dirt or gravel then you will probably want to drive some longer spikes into the shoulder of the road to attach your loops to.

If you only have concrete around you may have difficulty driving nails, while we don't sell anything for this specifically, you may want to get a hold of a hammer drill (used to drill concrete) and some sort of concrete anchors. These can typically be picked up at your local hardware store.

In some cases, where you only have concrete to attach to and where you have very low and slow moving traffic (such as a parking garage) you MAY be able to get by with using lots of tape to secure your hose. Be sure to sweep up first to remove as much debris as possible before taping the hose along it's full length.

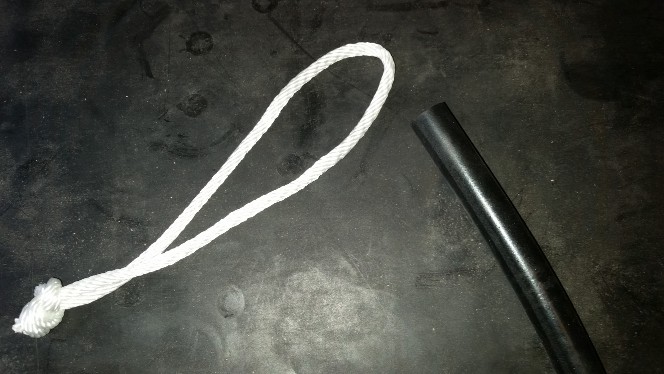

Once you have anchors in place you will be attaching the hose to the anchors using nylon rope loops. To do that you will simply take a loop and wrap it around the hose (feeding one end of the loop back through the loop itself). So now the rope should be around the hose with one end of the loop extending from the hose, with this end you will just slip it over the anchor. If you don't feel like the hose will hold in place well, you can also choose to add some duct tape to keep it from sliding, although this is optional and you should use your best judgement -- many people do not use tape on the loop grips. On the far end of the hose the if the hose is folded over slightly and zip-tied that will also help prevent the hose from pulling out of the loop.

You should pull the tubes so they are straight, but don't pull them so tight that they will be pinched shut by the loops. Just pull it straight where the hose has a little bit of tension and will not move around much. You will not want hose that is unsecured in the roadway, so during setup be sure to minimize the time that anything in the roadway is not secured down. Make sure any excess tube is coiled near the counter.

You will want to tape the hose to the roadway in a few places to help keep the hoses secured. Often just a piece or two of tape in the middle of each lane is good, but this varies from set-up to set-up, some people put several pieces of tape down and I've seen other set-ups where the hoses were taped down along the whole length of the tube. This all comes down to your judgement for the specific setup you are working on. You may get a better feel on how much tape you want to use after experience setting up a few counts.

Connect the tube(s) to the counter.

Check Your Counter

After you have set everything up and connected the tubes to your counter you should verify that the counter is actually collecting data before leaving it.

To do this you can either use a CountBuddy, CountBuddy II, or a laptop running TrafficViewer Pro.

In the case of the NanoCount 1000, you can watch the display for a few vehicles to be sure they are being properly counted.

In the case of the PicoCount counters, you can verify they are counting by connection up a laptop and watching the counter in "live data" mode, or if you have a CountBuddy or CountBuddy II, you can verify the hits by plugging it into the PicoCount counter. In the case of low volume setups, this may be difficult if there is no traffic. You could try using a sledge hammer to lightly tap the hose.

Your verification may show the counter over-counting, or under-counting. Over-counting can be corrected for by the software by changing the "Dwell Time" setting. In the case of the NanoCount 1000, there is a menu option to change your count "environment". Under-counting is another matter. If the unit is under-counting, you need to correct the problem before finishing the installation, software cannot fix this issue. Under-counting may be caused by a split or punctured hose, by too long of a hose run, or by the air switch sensitivity being too low. Often, in multi-lane installations, cars in the near lane(s) will register okay, but cars in the far lane may be missing occasional hits. In these cases, if the hose is good, make the hose run to the roadway as short as is practical. If this does not work, you may have to go to a larger inside diameter hose, which will give you larger signals.

Clear Counter Data

If you did not clear the data out of your counter in the office before taking it out in the field, you should go ahead and clear the counter's data now before leaving the unit to collect. This will clear old studies out of the unit so that your data overview screen will be more helpful and your download will go slightly faster. Clearing the data also syncs the unit's time to your computer's time, which can be extra helpful around daylight savings time or if the counter has crossed timezones.

Troubleshooting Count Problems

If you are missing hits on one or both channels you will need to do some troubleshooting to determine the cause of the problem. The most likely problem is a split or broken hose of some sort. Since hoses wear down over time and will eventually need replacing, it is good to do fairly regular inspections of your hose before using it. Toss out any hose you see physical problems with (splits or breaks of some sort). Some times a quick inspection of the hoses will still miss a split but it does help and can help prevent frustrating recounts.

If just one of your channels is missing hits pay attention to which one it is, and then swap the two hoses (physically leave them where they are, just pull the hoses off the nozzles and swap them). Now watch the data again, is the same hose still missing hits or did the problem stay with the channel? If the "A" channel was missing hits previously, and now the "B" channel is missing hits, then you know that you have a hose problem. You will need to swap that hose out with a new hose or at least check to make sure you're not accidentally pinching the hose shut where the grip is holding the hose down near the counter. If the problem remains with the same channel (if the "A" channel was missing hits, and you swap the hoses and the "A" channel is still missing hits) then you know the problem is with the "A" channel on the counter. You can try to inspect the nozzle of the counter to make sure there is no obvious blockage. If there is you can try to clear it out gently and try again (see Cleaning Your Units). If not, then you should swap your counter out with another counter and contact us to send your counter in for us to look over. If your unit is under warranty and the unit hasn't been physically damaged then repairing or replacing your unit will be at no charge.

If both channels are missing hits then you may have more than one problem and you will need to be sure and pay close attention to things as you troubleshoot the problem. If you have another counter, the easiest thing to do in this situation would be to swap the counter out with a new counter and if that new counter is behaving fine then the previous counter may have 2 bad channels on it (or if you are running long lengths of tube the channels may just not be sensitive enough for your hose length). You will want to mark the unit and send it in to us with a brief note. If the second counter also has the problem then you may have two bad hoses or you may have just pulled the hoses too tight and they may be pinched off, you could try relaxing the hose tension a little and checking the grips to make sure they're not pinching the hoses shut and try again. If they still do not work then you may need to swap both hoses out as they both may have been damaged by something.

If you swap tube out be sure to toss the bad tubing so you don't get it back into the mix. Likewise if you swap a counter out due to one of it's channels being bad you should make note of the serial number immediately and put a mark on the unit in some way (such as with a sticker or duct tape, or even a sharpie) so that you don't accidentally use it at another location until it is looked over.

After you fix the problem or replace the hose or counter, be sure to test again, repeating any steps as needed.

Keep in mind tube length... we don't sell hose over 50' in length as our counters are sensitive enough to detect air pulses from vehicles on 50' tubes. If you go longer than that you may run into problems with missed hits. If you need a longer run of hose you can try a larger inner diameter tube to see if that helps (the larger inner diameter will generate a larger air pulse). Otherwise you will need to cut your tubes shorter.

Safety

- You should purchase a safety vest if you do not already have one. A safety vest should be worn any time you are near the roadway.

- Never turn your back to oncoming traffic.

- Never leave unsecured items in the roadway.

- Be aware of traffic at all times.

- A second person can help out... they can help keep an eye on traffic, assist with the other side, or handle a sign for a busy roadway.

- Purchase some safety cones and place those on each side of the roadway where you will be working to help alert drivers to your presence.

- When your counter is attached to tubes, you should always be sure it is attached to something with the chain and lock just in case a tube somehow gets caught up with a vehicle.

Other Tips

- Lawn-mowers and street-sweepers are enemies of traffic counters.

- It can be very beneficial to contact the city or other company or agency responsible for lawn mowing or street sweeping in the area where you plan to set a counter.

- You can verify that there will be no scheduled lawn moving or street sweeping during your study. And you can let them know you will be doing so.

- You could place a traffic cone over the counter if it's on a lawn so that if somebody is going to mow they will see the cone and possibly the counter if they go to move the cone.

- And, of course it goes without saying, but be sure to pay attention to an obey all of your local laws.

Photos of count sites with two hoses

Related Articles

Adjusting dwells for the best results

Setting up for low speeds